Workplace Fatigue Risk Management System – Compliance Game Plan

While workplace fatigue has been around as long as workplaces have existed, the problem has assumed a new urgency. Labour shortages and rising wages are creating intense pressure on workers to work longer and sleep less. The inevitable buildup of fatigue and exhaustion is increasing the likelihood of workplace incidents, injuries and even deaths to the extent it leads to:

- Slowed reaction time;

- Reduced vigilance;

- Impaired decision-making ability;

- Poor judgment;

- Distraction during complex tasks; and

- Loss of awareness in critical situations.

Implement a Fatigue Risk Management System

So, what can you as an OHS coordinator do to help your company manage workplace fatigue risks’ The first step is to recognize’and get your company to recognize’that fatigue is a hazard that affects not just safety but also productivity and the bottom line. One study estimates that companies lose $1,967 per worker per year in lost productivity due to sleep loss. While not required by OHS laws, best practices dictate that you implement a fatigue risk management system as part of your larger OHS program. There are 12 elements your program should include:

1. Fatigue Management Policy

First, get your company to adopt a written policy expressly acknowledging that fatigue is a workplace hazard, outlining a practical strategy for managing it and defining the roles and responsibilities of management, supervisors, workers and other stakeholders in implementing the strategy.

2. Fatigue Hazard Identification

As with any other hazard, hazard identification is the first, crucial step in managing fatigue risks. There are 3 basic methods of identifying fatigue hazards:

- Reactive hazard identification seeks to identify existing fatigue hazards by looking at work schedules, fatigue and incident reports and other data generated after the fact;

- Proactive hazard identification involves taking active measures like walk-through inspections, interviews and use of software-based models to identify and quantify fatigue hazards displayed by workers; and

- Predictive hazard identification focuses on future fatigue hazards by examining planned duty schedules before they’re actually worked, such as via biomathematical modeling of sleep and fatigue based on scheduled duty periods.

3. Fatigue Hazard Assessment

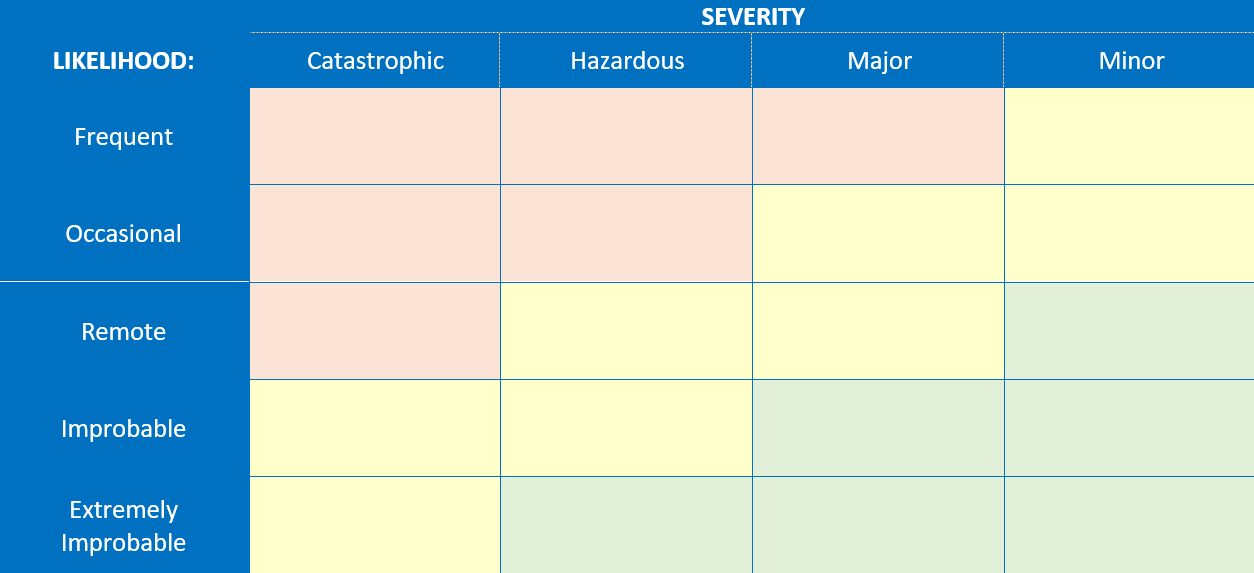

Once you identify fatigue hazards, you must assess them in terms of priority before deciding what, if anything, to do to manage them. One common approach is to use a matrix to categorize fatigue hazards based on their likelihood and severity, the way you might do with other hazards.

Table 1: Severity Matrix

Green: Low Priority

Yellow: Medium Priority

Orange: High Priority

4. Work Scheduling Controls

The next step is to implement appropriate controls to eliminate or at least minimize the risks you identify. The next 7 elements are key measures you can use to control fatigue risks, starting with work scheduling, which is a major contributing factor to fatigue risks. Accordingly, you can mitigate risks by ensuring that schedules provide ample time for rest, recovery and sleep. Examples:

- Establishing maximum hours for daily work hours, average weekly work hours and total hours over a 1- or 2-months period;

- Accounting for on-call work and work-related travel in managing work hours;

- Ensuring all workers have and take minimum breaks to rest, eat and rehydrate;

- Minimizing and limiting task changes, e.g., a maximum of 3 or 4 per day;

- Managing overtime, accrued leave balances and requests for leave; and

- Filling vacant positions as soon as possible so that remaining workers don’t have to take up the slack.

5. Shift Work Controls

Implement controls for shift and night work, such as, if possible:

- Structuring shifts to make work demands highest towards the middle of the shift and decrease towards the end;

- Avoiding split shifts and morning shifts that start before 6 AM;

- Allocating shift and night workers consecutive days off to allow for at least 2 full nights’ sleep, including some weekends;

- Overlapping consecutive shifts to allow enough time for communication at shift handovers and avoiding overtime allocation after afternoon or night shifts; and

- Keeping sequential night shifts to a minimum.

6. Safe Work Procedures

Implement safe work procedures for that provides for:

- Supervisor and co-worker fatigue monitoring;

- Recognizing the effects, signs and symptoms of fatigue;

- Assessing the level of fatigue risk; and

- Reporting and investigating incidents and near misses that may have been caused by fatigue.

7. Workplace Environment & Design

You can minimize fatigue risks by controlling the workplace environment. Examples:

- Avoid working during periods of extreme temperature or minimize exposure time via job rotation;

- Provide a cool area where workers can take a rest break and rehydrate in hot work environments;

- Install ventilation and mechanical cooling devices in hot, small and enclosed spaces such as truck cabins;

- Provide facilities for rest, sleep, meal breaks, onsite accommodation (if appropriate). Install adjustable, low-vibration seats in machinery and vehicles and provide low vibration hand held equipment; and

- Ensure the workplace is well lit.

8. Fatigue Reporting System

Establish a simple and straightforward system workers can use to report incidents caused by fatigue or when they feel so fatigued that they’re unfit to work safely. Provide a fatigue self-reporting template to gather the appropriate information and instruct supervisors what to do when workers report that they’re unfit to work due to fatigue.

9. Fatigue Incident Investigation

Be sure that your current procedures for investigating incidents and near misses account for fatigue’specifically, whether fatigue was a factor, the role fatigue played, why the worker was fatigued and why existing fatigue-control mechanisms failed.

10. Fatigue Management Training & Education

Train management and workers on the dangers of fatigue and your fatigue risk management system, including:

- The hazards of working while fatigued and the importance of being well-rested;

- The impact of chronic fatigue on personal relationships, mental/physical well-being and general happiness;

- How fatigue can be managed and minimized;

- The quantity and quality of sleep necessary to manage fatigue;

- The basics of sleep physiology, circadian rhythms and what’s considered adequate

- sleep;

- Sleep hygiene, that is, how to obtain adequate quality and quantity of sleep;

- Sleep disorders’why they matter, how to spot them and what to do about them;

- The importance of diet, exercise and the and management of stress and other health conditions that affect fatigue;

- How workers can recognize fatigue in themselves or their co-workers; and

- Alertness strategies to use at work, such as appropriate use of caffeine, rest or exercise breaks and social interactions.

11. Sleep Disorder Management

Help workers manage themselves by teaching them to recognize the dangers of fatigue and the importance of getting enough sleep. If appropriate, let workers take a nap after extended physical activity or other circumstances likely to cause extreme fatigue. One of the most common causes of fatigue is an underlying sleep disorder. So, if possible, companies should implement sleep disorder management programs that screen workers for sleep disorders and help them get appropriate treatment.

12. Internal & External Auditing Process

As with any safety management system, your fatigue risk management system should be regularly audited to ensure that it’s effective and up-to-date and to implement any corrections or improvements.