Having appropriate portable fire extinguishers at your workplace may literally be the difference between life and death. That’s because if a fire breaks out, the consequences will likely be determined in those critical first few moments after it starts, aka, the early or “incipient stage”:

- 93% of all fire deaths occur after the fire progresses beyond the incipient stage;

- 95% of direct property damage caused by fires also happens after the incipient stage; and

- Most fires can be put out during the incipient stage before ever reaching fatal and catastrophic levels.

In addition to saving lives and property, implementing a portable fire extinguishers safety policy and plan is a legal obligation that’s strictly enforced. Here’s a 13-step Game Plan you can implement to ensure proper use, care, and maintenance of portable fire extinguishers as well as compliance with OHS regulations and fire code rules.

Step 1. Perform a General Fire Hazard Assessment

Fire extinguishers are an integral part of a broader strategy for identifying, assessing, and controlling fire hazards at the worksite. The first step is to designate one or more competent persons perform a general fire safety assessment that takes into account all of the materials, equipment, tools, operations, and jobs at the site. Specific steps:

- Identify all of the flammable, combustible, and explosive substances at your site;

- Evaluate how each of those materials is used, handled, and stored;

- Identify all ignition sources, that is, heat, flames, sparks, and other things that can cause flammable, combustible, and explosive substances to ignite;

- Identify all work operations involving fire hazards, such as welding and hot work;

- Observe workers performing these operations;

- Identify other fire hazards;

- Evaluate the fire safety aspects of the building’s construction, considering such things as ease of ingress and egress, use of fire-resistant materials, occupancy levels, installation of sprinklers, etc.;

- Evaluate your current emergency response plan;

- Evaluate the site’s fire alarm and notification equipment and methods;

- Assess whether adequate portable fire extinguishers and other firefighting equipment are on hand;

- Interview workers and supervisors about fire hazards; and

- Review written records of worker complaints or safety committee recommendations involving fire safety.

Step 2. Check for Unsafe Practices & Equipment

The way people work might contribute to fire dangers. So, be on the lookout for as fire safety risk factors. Common examples:

- Unsafe use, handling, and storage of flammables, combustibles, and explosives;

- Unsafe carrying out of hot work or other operations that pose fire hazards;

- Overloading of electrical outlets;

- Frayed or damaged wiring or electrical equipment;

- Proximity of flammable, combustible, and explosive substances to heat or ignition sources;

- Unsafe accumulations of flammable or combustible dusts, fumes, or vapours in the air;

- Unsafe accumulations of flammable or combustible dusts or materials on floors, walls, surfaces, or equipment;

- Accumulations of dangerous debris such as oily rags;

- General failure of workers to follow good housekeeping and fire prevention practices; and

- General lack of fire safety awareness among workers.

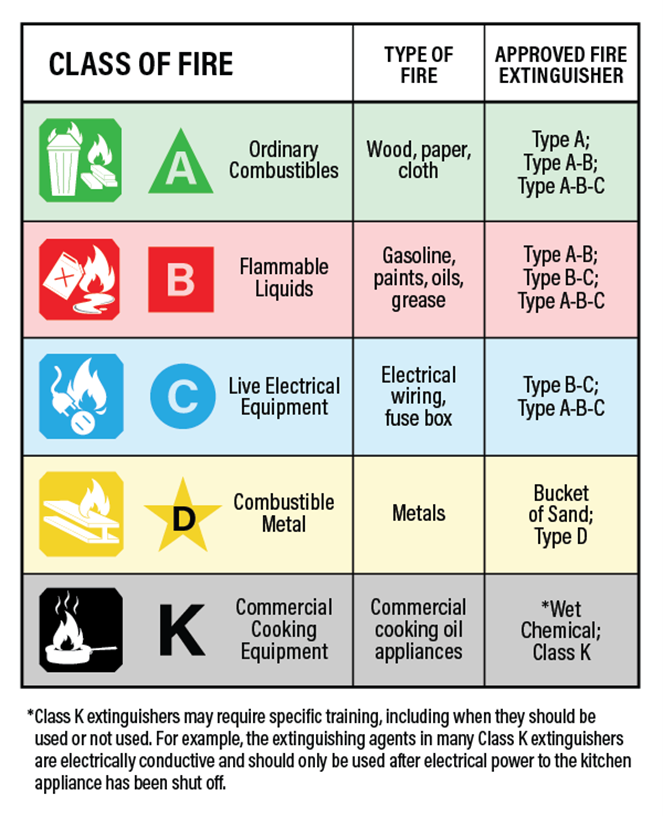

Step 3. Determine Types of Fires That May Break Out at Your Workplace

Fires are grouped by categories or classes based on the fuel they burn. Identifying the category or class of a potential fire is crucial for determining how to prevent and extinguish it. So, you should determine the class(es) of each fire hazard you identify during your general hazard assessment:

Table 1: The 5 Classes of Fires

| Class | Fuel Source(s)/Other Defining Trait(s) |

|---|---|

| Class A | Ordinary combustible materials such as wood, cloth, paper, rubber, plastics. |

| Class B | Flammable or combustible liquids, petroleum greases, tars, oils, paints, solvents, lacquers, alcohols, flammable gases. |

| Class C | Energized live electrical equipment such as motors, power tools, appliances. |

| Class D | Combustible metals such as magnesium, titanium, zirconium, sodium, lithium, potassium. |

| Class K | Cooking appliances or combustible cooking materials such as vegetable or animal oils and fats. |

Step 4. Select Appropriate Portable Fire Extinguishers

Select portable fire extinguishers of a type designed to fight the particular classes of fire that you identified during your fire hazard assessment.

Table 2: Class of Portable Fire Extinguisher Approved for Each Class of Fire

| Class of Fire | Type(s) of Approved Portable Fire Extinguisher |

|---|---|

| Class A (ordinary combustibles) |

Type A Type A-B |

| Class B (flammable liquids) |

Type A-B Type B-C Type A-B-C |

| Class C (electrical) |

Type B-C Type A-B-C |

| Class D (combustible metals) |

Bucket of sand |

| Class K (combustible cooking materials or appliances) |

Class K wet chemical* |

* Class K fire extinguishers require special training for safe use.

Another way to distinguish among types of portable fire extinguishers is by the materials they use to extinguish a fire.

Table 3: Portable Fire Extinguisher Types Comparison

| Portable Extinguisher Type | Class | Range | How Long Before It Empties | Other Key Characteristic(s) |

|---|---|---|---|---|

| Water | A | Long | 60 seconds | *Fight re-ignition *Don’t use for electrical fires |

| CO2 | B & C | Short | 10-20 seconds | *Displace oxygen and may make breathing difficult *Don’t use in confined spaces |

| Dry Chemical | B, C & some A |

Moderate | 10-25 seconds | Leave potentially harmful residue |

| Liquid Gas | B, C & some A |

Short | 10 seconds | May make breathing difficult |

| Chemical Foam | A & B | Moderate | 10-30 seconds | Leave potentially harmful residue |

| Bucket of Sand/Dry Powder | D | N/A | N/A | Class D firefighting may require special equipment |

| Media designed to extinguish combustible metals like magnesium, sodium, titanium, and potassium | D | Moderate | Quickly | Use a Class D extinguisher that’s compatible with the metals present |

| Wet Chemical | K | N/A | N/A | *Fight re-ignition *Leave potentially harmful residue |

Step 5. Ensure Portable Fire Extinguishers Are Properly Marked

Portable fire extinguishers must be marked to indicate the class of fire they’re designed to fight. Most of Canada uses the following National Fire Protection Association (NFPA) symbols for marking fire extinguishers.

Table 4. NFPA Portable Fire Extinguisher Markings

PRODUCTION: Source of graphic: CCOHS https://www.ccohs.ca/oshanswers/safety_haz/fire_extinguishers.html

Step 6. Implement Procedures for Safe Use of Portable Fire Extinguishers

Create and implement written procedures for safe and effective use of the portable fire extinguishers located at your workplace based on the so-called PASS system:

- Pull the extinguisher pin;

- Aim the extinguisher;

- Squeeze the top handle or trigger; and

- Sweep the fire area with the extinguisher until the extinguisher runs out.

Safe work procedures should also include fire evacuation instructions in case extinguishing fails.

Step 7. Ensure Workers Who Use Fire Extinguishers Wear Proper PPE

Your workplace emergency response plan should assign fire extinguisher use duties to specific workers. Ensure that such workers are equipped with and use appropriate PPE and protective clothing for firefighting, including:

- Eye and face protection;

- Head protection;

- Fire-retardant boots or other protective footwear;

- Body, arm, and leg protection;

- Gloves, glove systems, and other hand protection; and

- Respiratory protective equipment (especially for indoor structural firefighting).

Step 8. Ensure Portable Fire Extinguishers Are Properly Installed

Ensure portable fire extinguishers are properly installed in clearly visible locations that are readily accessible to workers in accordance with the height and spacing requirements of your jurisdiction’s Fire Code. Fire extinguisher locations should be clearly marked by signs and kept unobstructed at all times. The fire extinguisher should also be of a proper size under Fire Code requirements.

Step 9. Ensure Portable Fire Extinguishers Are Inspected at Least Once a Month

Fire Codes and NFPA standards require the owner or occupant of the site to have a competent person manually inspect portable fire extinguishers when they’re first installed and visually inspected at least once a month thereafter to verify, at a minimum, that:

- They’re securely fastened and well supported;

- They’re fully charged and ready to use;

- They’re within easy reached without any obstructions;

- They’re properly marked;

- The pressure gauge reading or indicator is in the operable range or position;

- They have clear and unobstructed discharge openings; and

- They have their ring pin in place and seal in place.

Certain fire extinguisher types may also require additional or special inspection. Example: Wheeled extinguishers must be inspected for tire and wheel condition.

You must also take immediate corrective action if the inspection reveals any deficiencies in the equipment. That includes taking fire extinguishers out of service if the cylinder or shell threads are damaged, there’s pitting due to corrosion, or the extinguisher has been burned in a fire. Damaged equipment should be replaced or repairs by properly certified personnel in accordance with manufacturer’s instructions before they’re put back into service.

Step 10. Keep Proper Records of Portable Fire Extinguisher Inspections

The owner or occupant must keep records including tagging of each extinguisher documenting that all required inspections have been carried out. Inspection records may be paper or electronic and must list the date of inspection, signature or initials of the person who performed the inspection, and comments. Monthly inspection records must be retained for at least 12 months.

Step 11. Ensure Portable Fire Extinguishers Are Properly Serviced & Maintained

Portable fire extinguishers must be serviced and maintained in accordance with manufacturer’s instructions and the requirements pertaining to the particular type of extinguisher set out in the applicable Fire Code and version of NFPA 10, Standard for Portable Fire Extinguishers. The latter requires “annual external examination” by a qualified person of each extinguisher’s:

- Physical condition;

- Seals or tamper indicators; and

- Boots, foot rings, and attachments.

“Annual internal examination” is also required for certain types of fire extinguishers, such as wetting agent, stored-pressure loaded stream and antifreeze, pump tank water and pump tank, calcium chloride based and dry chemical, and cartridge- and cylinder-operated extinguishers with mild steel shells.

Each fire extinguisher must have a securely attached tag or label indicating that maintenance was performed and listing, at a minimum the:

- Month and year maintenance was performed;

- Person performing the work; and

- Name of the agency performing the work.

Step 12. Ensure Portable Fire Extinguishers Are Properly Tested

NFPA 10 requires hydrostatic testing of fire extinguisher cylinders and cartridges at regular intervals depending on fire extinguisher type.

Table 5: NFPA Hydrostatic Testing Intervals for Portable Fire Extinguisher Types

| Fire Extinguisher Types | Hydrostatic Testing Intervals |

|---|---|

| Stored-pressure water, water mist, loaded stream, and/or antifreeze | Every 5 years |

| Wetting agent | Every 5 years |

| AFFF (aqueous film-forming foam) | Every 5 years |

| FFFP (film-forming fluoroprotein foam) | Every 5 years |

| Dry chemical with stainless steel shells | Every 5 years |

| Carbon dioxide | Every 5 years |

| Wet chemical | Every 5 years |

| Dry chemical, stored-pressure, with mild steel shells, brazed brass shells, or aluminum shells | Every 12 years |

| Dry chemical, cartridge- or cylinder-operated, with mild steel shells | Every 12 years |

| Halogenated agents | Every 12 years |

| Dry powder, stored-pressure, cartridge- or cylinder-operated, with mild steel shells | Every 12 years |

Source: NFPA 10, Standard for Portable Fire Extinguishers, 2022 Ed., Table 8.3.1

The organization that performed the hydrostatic tests must keep records of the testing until the test period expires or the cylinder is tested again. Regular testing is also required for hose assemblies, pressure gauges, and drying equipment.

Step 13. Ensure Workers Receive Training on Portable Fire Extinguisher Use

Basic portable fire extinguisher use should be part of the general fire safety and prevention you provide to workers. At a minimum, such training should warn workers not to use an extinguisher unless they’re trained to do so and cover:

- The different classes of fires;

- The types of extinguisher(s) approved for fighting each class;

- The PASS system of fire extinguisher use and company’s safe work procedures for extinguishing fires;

- The PPE required for firefighting and how to use it;

- Evacuation instructions in case fire extinguishing fails; and

- Fire department contact information and instructions.

Be sure that workers actually understand their fire extinguisher safety training and are capable of following it. Recommendations:

- Quiz workers on the training after you deliver it;

- Make them demonstrate use of the PASS system and emergency evacuation procedures; and

- Hold fire drills requiring workers to use fire extinguishers and execute emergency evacuation.

STEP 1: Enter your name & company email address

STEP 2: Select Company Size

ALMOST DONE - STEP 3: Additional Details

Unlock Full Access with a 14-Day Free Trial

Gain unlimited access to premium articles, expert insights, and valuable industry resources. Sign up now and experience the benefits of a risk-free trial!