Study Warns of Poor Safety Practices at Refineries Using Hydrofluoric Acid

The United Steelworkers recently released a study”A Risk Too Great, Hydrofluoric Acid in U.S. Refineries”on the use of hydrofluoric acid by refineries in the US. It found that refineries that used this hazardous substance in their alkylation process to make clean-burning gasoline didn’t have adequate safety systems in place and weren’t prepared to handle a major release.

The lessons and recommendations from this study can be useful for refineries and other workplaces in Canada that also use hydrofluoric acid and whose workers are also at risk.

Example: Suncor Energy Products Inc. was fined $200,000 in Ontario for two incidents involving worker exposure to hazardous chemicals, including hydrofluoric acid. In that incident, two workers were draining a piping system of petroleum and hydrofluoric acid at a refinery. Vapors drifted downwind and 23 other workers required treatment for potential exposure to the acid.

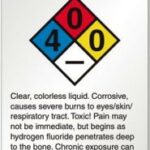

Hydrofluoric acid is a highly toxic chemical. Exposure to it can cause deep severe burns and damage the eyes, skin, nose, throat and respiratory system. And at high enough exposures, it can kill.

In addition, if hydrofluoric acid is released into the atmosphere, it quickly forms a dense vapour cloud that hovers near land and can travel long distances, endangering not only workers but anyone living near these refineries in the event of a major release.

In the study, safety experts examined the safety of refineries using hydrofluoric acid alkylation by reviewing survey results and data from OSHA, the US Chemical Safety Board and the industry to see how well these refineries were managing the risk of a hydrofluoric acid release.

Key findings:

- At three-quarters of the refineries surveyed, a total of 131 hydrofluoric acid-related incidents or near misses had occurred in the previous three years. Sixteen sites said workers either were or could have been injured; half said these events could have caused injuries to people in the community.

- More than half of the site survey teams reported that 26 out of 32 safety systems at the refineries were less than very effective in maintaining the integrity of the hydrofluoric acid alkylation processes and related processes, such as storage and transfer, and in handling an acid-related emergency.

- Almost two-thirds of the sites were less than very prepared in providing emergency PPE for on-site workers who might need it during a release.

- More than half of the survey teams rated on-site and off-site emergency responders and medical personnel as being less than very prepared for an on-site emergency’and they were even less prepared for a release spreading into the local community.

Seven Steps to Safer Refineries

The study says the long-term solution to addressing the hazards posed by hydrofluoric acid use is to replace hydrofluoric acid alkylation with safer systems not requiring the use of so toxic a chemical. Meanwhile, existing alkylation units can and must be made safer. In particular, the study recommends that the industry:

1. Commit to ending the use of hydrofluoric acid alkylation and replacing it with safer alternatives as soon as possible.

2. Develop, build and test pilot alkylation units using safer chemicals and processes, sharing lessons from those operations to speed the transition to full-scale safer alternative alkylation processes across the industry.

3. Work cooperatively with all stakeholders to educate site workers, on- and off-site emergency responders and receivers, and the public about the dangers of hydrofluoric acid.

4. Make existing hydrofluoric acid alkylation processes systems safer by improving process integrity, mitigation systems and emergency response, and by converting to the use of modified-hydrofluoric acid.

5. Create an open and transparent system for reporting hydrofluoric acid-related releases, near misses and process upsets, both within and outside the company, so that similar events can be avoided.

6. Work with unions to promote effective process safety programs based on rigorous hazard identification and correction.

7. Increase staffing to a level that will be effective in preventing, preparing for and responding to potential hydrofluoric acid alkylation unit emergencies.